HiLiQi, having established itself in the turbocharger industry for 20 years, is the trusted name for precision engineered turbochargers. We supply an extensive range of OE-quality and cost-effective products to customers and offer turbochargers replacement solutions that enhance driving experience.

HiLiQi is home to a group of highly-qualified mechanical engineers with over 30 years of experience in the turbocharger industry and a complete mastery of simulation tools. With the support of state-of-the-art equipment, they are the one who make HiLiQi’s quality replacement turbochargers possible.

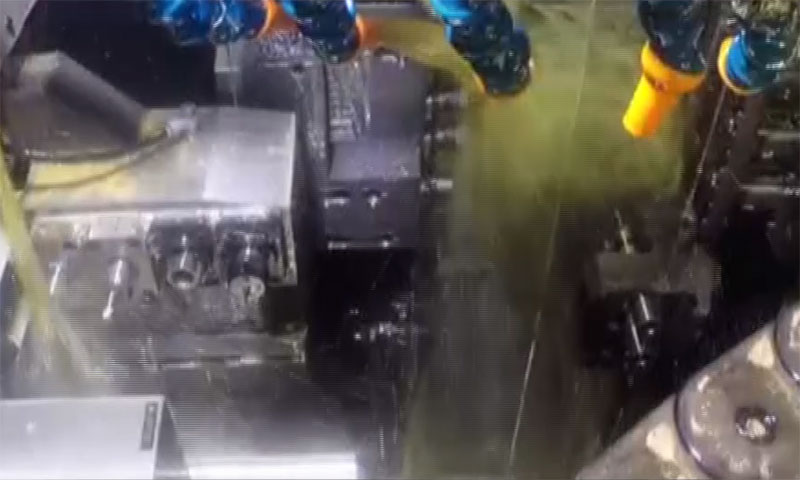

Three-Coordinate Measuring Machine & 3D Scanner – used to measure turbocharger parts and work out the specifications and geometric features. Along with 3D modelling software and 3D printing, engineering drawings are created, which plays an important role in product manufacturing.

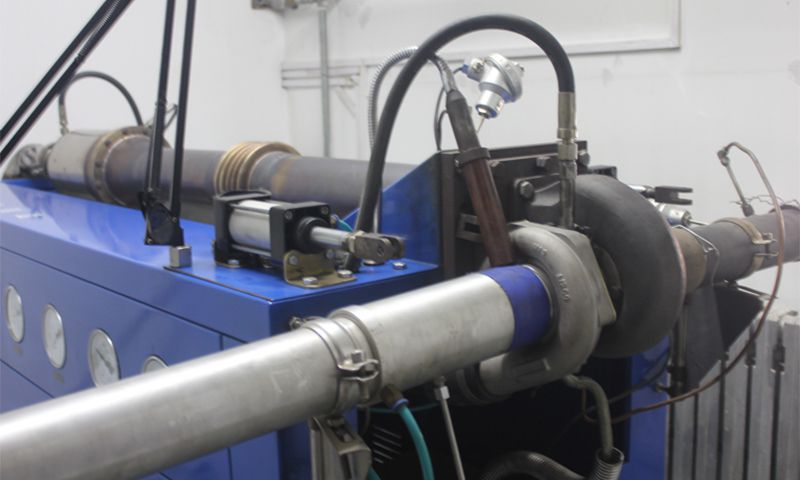

Turbocharger Production Test Rig- tests turbochargers for their performance and precision, such as leakage in turbine and compressor housings as well as performance hysteresis, actuator response time and actuator oil consumption.

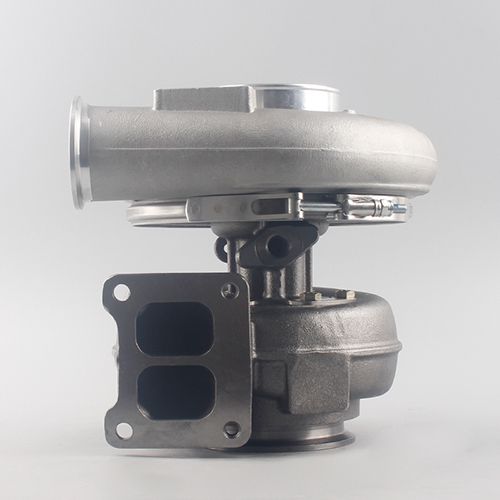

HiLiQi supplies more than 1,000 complete turbochargers of OE quality, covering over 20 world-renowned engine brands such as Cummins, Caterpillar, Komatsu, Deutz, Volvo, Perkins, JCB, John Deere, etc. At HiLiQi, you're getting the finest-quality replacement turbochargers that are reasonably priced.

HiLiQi assembly line features a full traceability system and rigorous inspection procedures, including critical tests of axial clearance, diametrical clearance, and air leakage.

Our coordinate measuring machine boasts a detection accuracy of up to 0.0001mm, enabling precise data collection for length, width, height, flatness, straightness, roundness, cylindricity, line profile, surface profile, perpendicularity, parallelism, and circular run-out. The collected data is then compared with design blueprints to identify discrepancies and continuously improve product performance to achieve optimal results.

- At the final stage of our development, new products are put to test for their safety, performance, and quality.

- Balancing test - HiLiQi turbocharger is balanced on a high speed balancing machine which accelerates the product through its full operating speed to ensure that the turbo does not vibrate excessively during operation or suffer failure.

- Simulations - for examination and optimization of turbine efficiency, aerodynamics, bearings, lubricant film pressures, etc.

Taking product quality as the top priority, HiLiQi enforces the strictest policy and procedures in all of our manufacturing process to certify that only perfect and high-performing products enter the stock. Thanks to our commitment to quality, the warranty return rate of our products remains extremely low.

HiLiQi is equipped with advanced inspection systems, including a Coordinate Measuring Machine (CMM) and a UK-imported High-Speed VSR Balancing System, ensure precision-grade quality for every turbocharger. Production is fully certified under the IATF 16949 Quality Management System, and the company is recognized as a National High-Tech Enterprise in Beijing. All manufacturing processes adhere to strict environmental compliance standards.

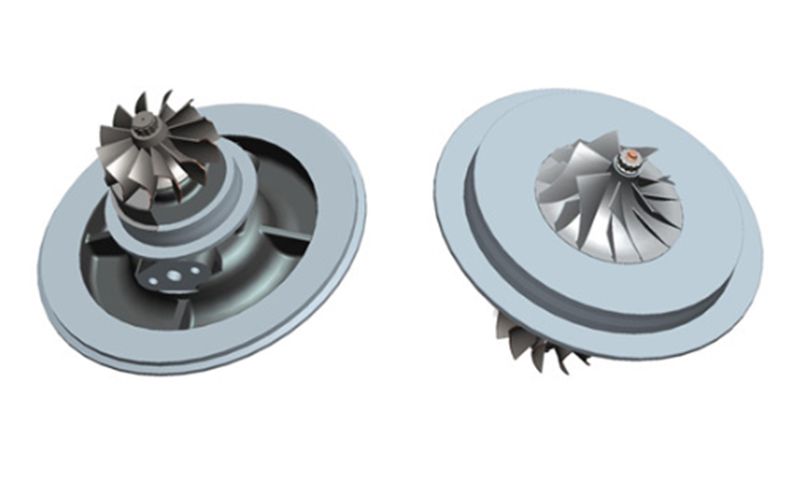

HiLiQi selects components that meet or exceed OEM specifications, including high-strength alloy turbines, precision bearings, and heat-resistant housings.

The materials of HiLiQi turbocharger parts are what define its superior quality. Minimizing the cost of production is not in our primary consideration, but the product quality is. With the firm belief that better quality of raw materials means longer-lasting parts, we always search for the best sources of materials that meet OEM standards.

- Axle HiLiQi turbine wheel axles, made out of 42 chrome molybdenum, demonstrate strong resistance to abrasion.

- Turbine wheel K418 turbine wheel, marked by its high hardness, is far less likely to suffer deformation or breakdown than K413, a cheaper option for many other suppliers.

- Bearings H26Cu thrust bearing & floating bearing processed by high procesion CNC Technology demonostrates high hardness and resistance to corrosion.

Under close inspection and supervision, our products are engineered for maximum performance and longevity

- Dynamic balancing Compressor wheel, turbine wheel, turbine shaft, and other key parts are all dynamically balanced to the correct balancing specification so as to improve longevity.

- Testing For Sealability Sealability is essential for a quality turbo. Each turbo has to be tested for sealability to avoid oil leakage caused by improper assembled tolerance.

- Testing For OE compatibility A range of typical engine operating conditions are simulated to ensure that the turbo is perfectly compatible with the OE engine.