Turbocharger parts

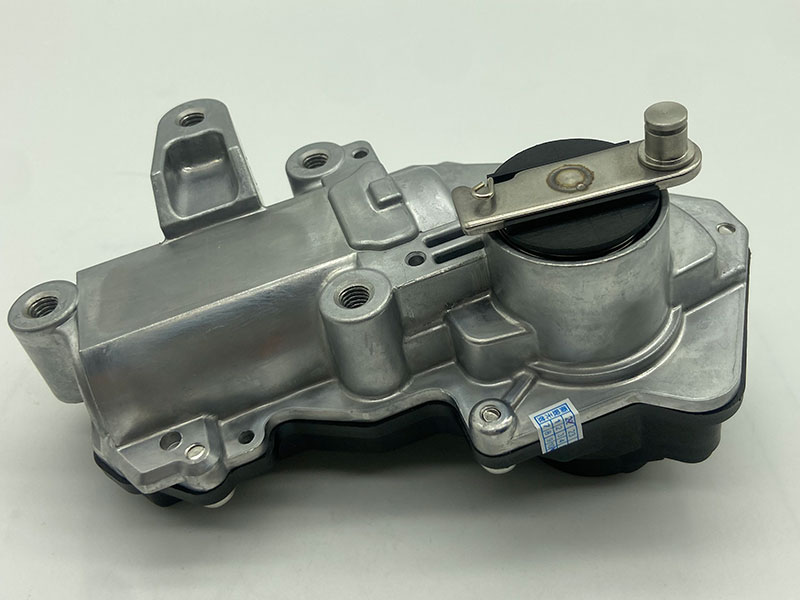

Material:ZL101: aluminum alloy

Processing technic: Undergo heat treatment.

Increase hardness, toughness, and prolong material

life span greatly.

Material used: ZL101 Aluminum alloy

Processing technique: Undergoes heat treatment to significantly enhance hardness, toughness, and extend material lifespan.

Material: QTSiMo ductile cast iron with high hardness and good ductility.

Processing technicz: cleaning, making surface clean and smooth.

Material used: QTSiMo Ductile Cast Iron

Processing technique: Polished to achieve a smooth and pristine surface, with excellent strength and ductility.

CW713R, Copper bar

Processing technic: CNC production

Higher hardness and smoothness.

Material used: CW713R, Copper Bar

Processing technique: Uses CNC production techniques, ensuring superior hardness and an exceptionally smooth finish. CW713R copper bars are known for their outstanding mechanical properties, including high strength and excellent corrosion resistance.

Material used: C355 cast aluminum alloy; Forged billet wheel; Titanium alloy wheel

Advantages of Titanium Alloy Wheel: Titanium alloy wheels have exceptionally high strength, more than twice that of ordinary steel, with outstanding performance in tensile strength, compression resistance, bending resistance, and vibration resistance. This remarkable durability ensures that they can withstand the most demanding conditions, offering exceptional reliability.

Its outstanding corrosion resistance minimizes maintenance requirements, leading to lower operational costs. This not only enhances production efficiency but also ensures long-term performance and value.

K418 / INCO 713C, high temperature alloy steel, melting point up to 1295-1345℃.

We do not use: K413, can’t endure high temperature, easy to break.Turbine shaft:42CrMo alloy steel with high hardness and good ductility.

Material used: K418 / INCO 713C, a high-temperature alloy steel with a melting point of 1295-1345℃

Unlike K413, which cannot withstand high temperatures and is prone to breaking, K418 / INCO 713C ensures reliability and longevity, offering superior strength and resistance to thermal stress. The turbine shaft is made from 42CrMo alloy steel, known for its high hardness and excellent ductility. This combination provides the necessary toughness to handle the intense operational demands while maintaining flexibility to prevent fractures.

H62, can bear heavy working load.

Machined from cooper bar

Processing technic: CNC production

Higher hardness and smoothness.

Not normal powder metallurgy technic, which is easy to be break.

Material: H62 Copper Bar

Processing technique: Uses CNC production techniques, ensuring superior hardness and an exceptionally smooth finish, far surpassing the quality of traditional manufacturing methods. Unlike standard powder metallurgy techniques, which can result in materials prone to breaking, our CNC production process guarantees enhanced durability and strength. H62 copper bars are able to withstand heavy working loads, making them ideal for demanding applications.

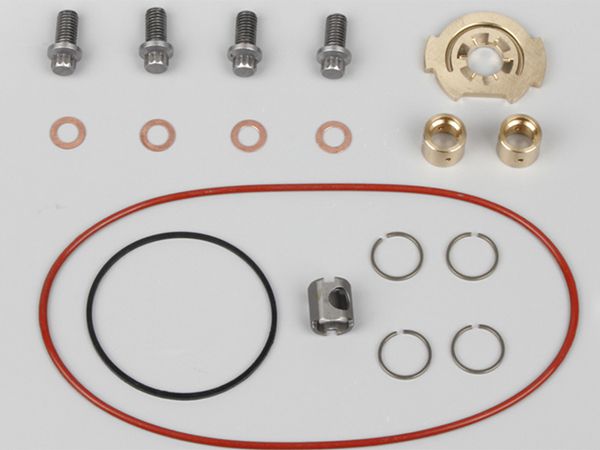

At HiLiQi, we are dedicated to providing comprehensive solutions that include all the necessary accessories to meet your needs. Whether you’re looking for complete turbocharger systems or specific components, we have everything you need to ensure your equipment operates at its best.

Depending on the model, the minimum order quantity can vary, typically ranging between 30 and 100 units. For detailed specifications and personalized assistance, please feel free to reach out to our sales team via email. We are here to help you find the perfect solutions tailored to your specific requirements.